The last 3d print I did was in August 2023 (spice rack boxes). This time around, I had a need of something to hang Philips Hue motion sensors from. Ideally without making holes in the walls.

The exercise took most of the weekend. Or at least, 3d printer was active for a lot of it. I did not spend that much time designing the thing obviously.

My 3d printing process

I used to use the Fusion 360 design tool but awhile ago I realized that describing geomery is more of a thing for me than drawing it out using a mouse. So I switched to OpenSCAD. Its language is .. an acquired taste, though, so I am solidpython2 to generate the .scad files out of Python script which describes the geometry I want.

The .scad files are then converted to .stl files (by openscad), and then I slice them using https://ultimaker.com/software/ultimaker-cura/ to gcode for my 3d printer. 3d printing is handled by Raspberry Pi (I don’t even remember which model) that is dedicated to 3d printing and runs OctoPrint.org and directly attacked to my Tevo Flash.

As the most recent 3d print was ‘only’ bit over year ago, I upgraded Cura, but OpenSCAD (release) version is still from 2021, and my OctoPrint is only few versions behind so I decided not to upgrade that either.

Saturday

I iterated through most of the model design during it, although printed only two iterations of it. I had used my last PLA (white) spool during my previous printing exercise, so I had to switch to HDGlass PETG I had in my storage.

The initial printing efforts were bit painful:

- I had issues getting PETG to stick to my magnetic printing plate

- Solution was to pre-heat the bed well in advance

- I had issues with PETG sticking too well to the bed, after it cooled down

- Initially I tried brute force flexing of the magnetic plate; this didn’t help although the structure itself broke down somewhat. Chisel didn’t help either (although I managed to scratch my fingers with it), nor did even hammer and chisel combination.

- Solution was freezer; perhaps warming it up again would have helped too but I was too impatient.

- The printer itself was somewhat ornery

- Clicking sounds (which was presumably due to the hot end being too cold, and extruder unable to exture; I realized this only the following day)

- Some power problems (it turned off at least twice on its own)

Sunday

Six printing attempts and some more design iterations. The printing attempts were quite mixed bag:

- When I tried using tape on the hotbed, it worked reasonably well but tape was basically used after one go

- Opening door to outside air cooled the 3d printer bed too much, and one print failed that way (=> hello, bad air quality by having closed doors and 3d printer. Luckily this was not ABS print..)

At some point I read bit more and though on the extruder noises and stickiness, and basically boosted bed temperature and hot end temperature quite a bit, and with pre-heat, problems were simply gone. And as long as I detached the print before it cooled down (by flexing the magnetic plate), there were no issues with that either.

Anyway, I printed few more experimental designs and also one copy of the final design. Final copy I printed early on Monday morning.

Design evolution

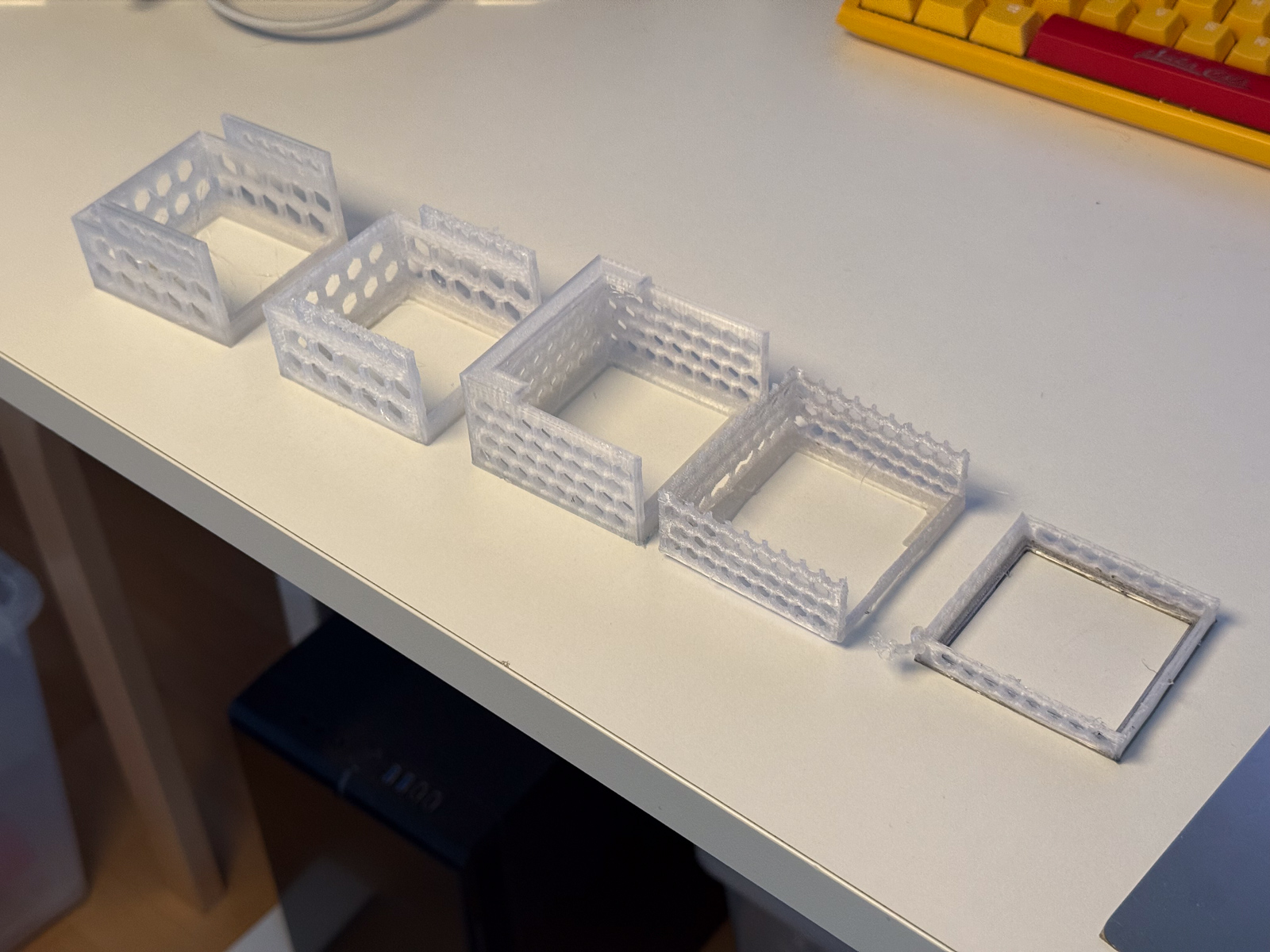

From right to left:

- First I wanted to make sure what the tolerances were => printed with 1mm border, and that seemed fine, so aborted print midway (this was on Saturday)

- I wanted to experiment bit with different wall designs - the multihole design seemed bit wasteful in the end, as it requires still nontrivial sized walls to be sturdy. Initial walls were made at 2mm width, but I settled on 3mm later.

- Third iteration was attempt to check if the top part to prevent Hue from dropping off was necessary; it was not. I also made it too large by overthinking about how much space you need to insert the device into, but that’s what (fast) prototypes are for.

- Fourth one was pretty close to final design, but the small holes for attachment were bit too near the top, and I was concerned about durability of the design, so I added some more space there.

- Final one was the final design.

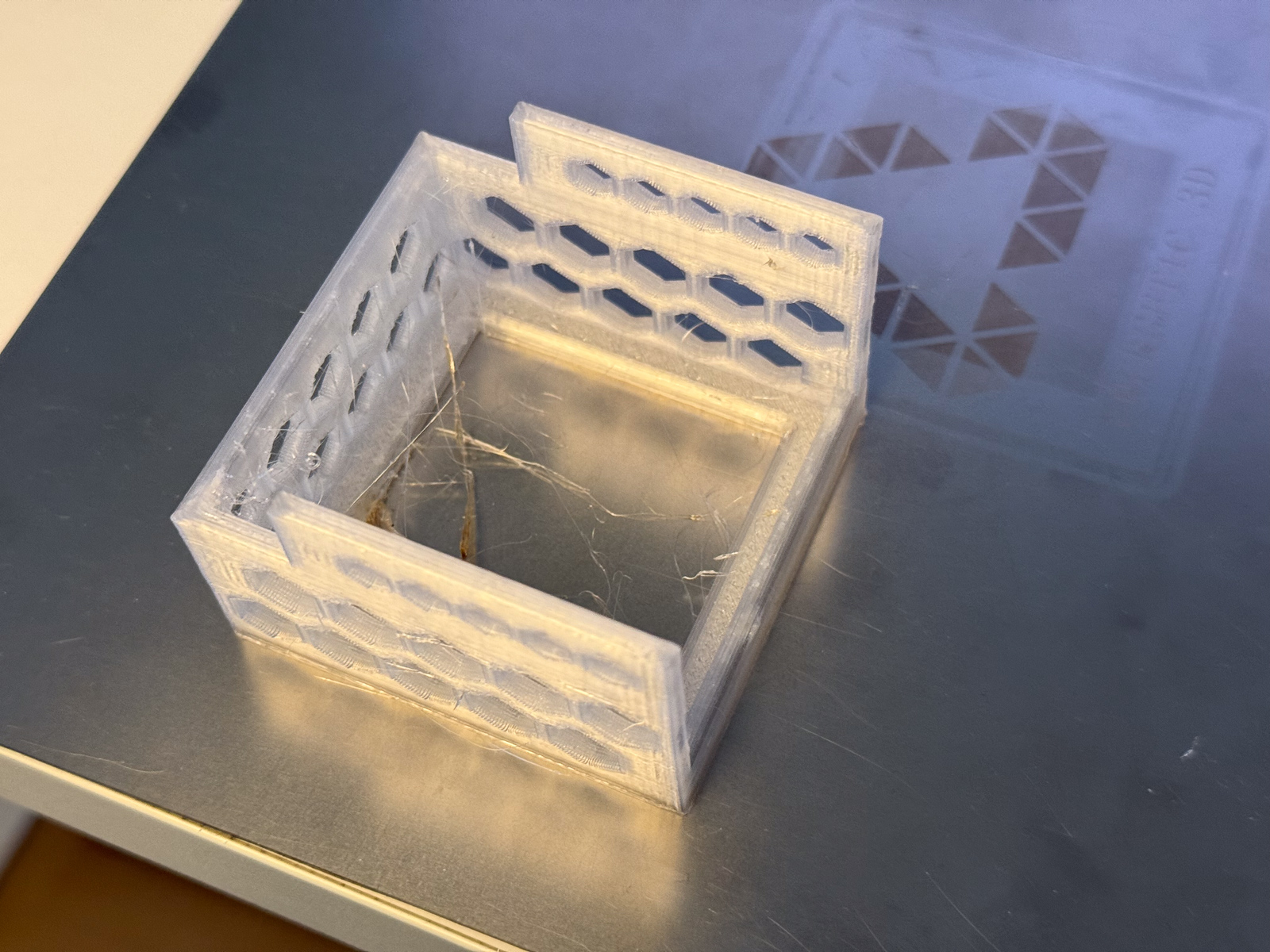

Here’s the final design fresh out of the printer. I am not sure why there is quite a bit of stringing still, and judging by the brownish hue of some of them, the temperature is likely slightly too high (Cura uses +10 degrees on top of what I configured for first layers).

Summary

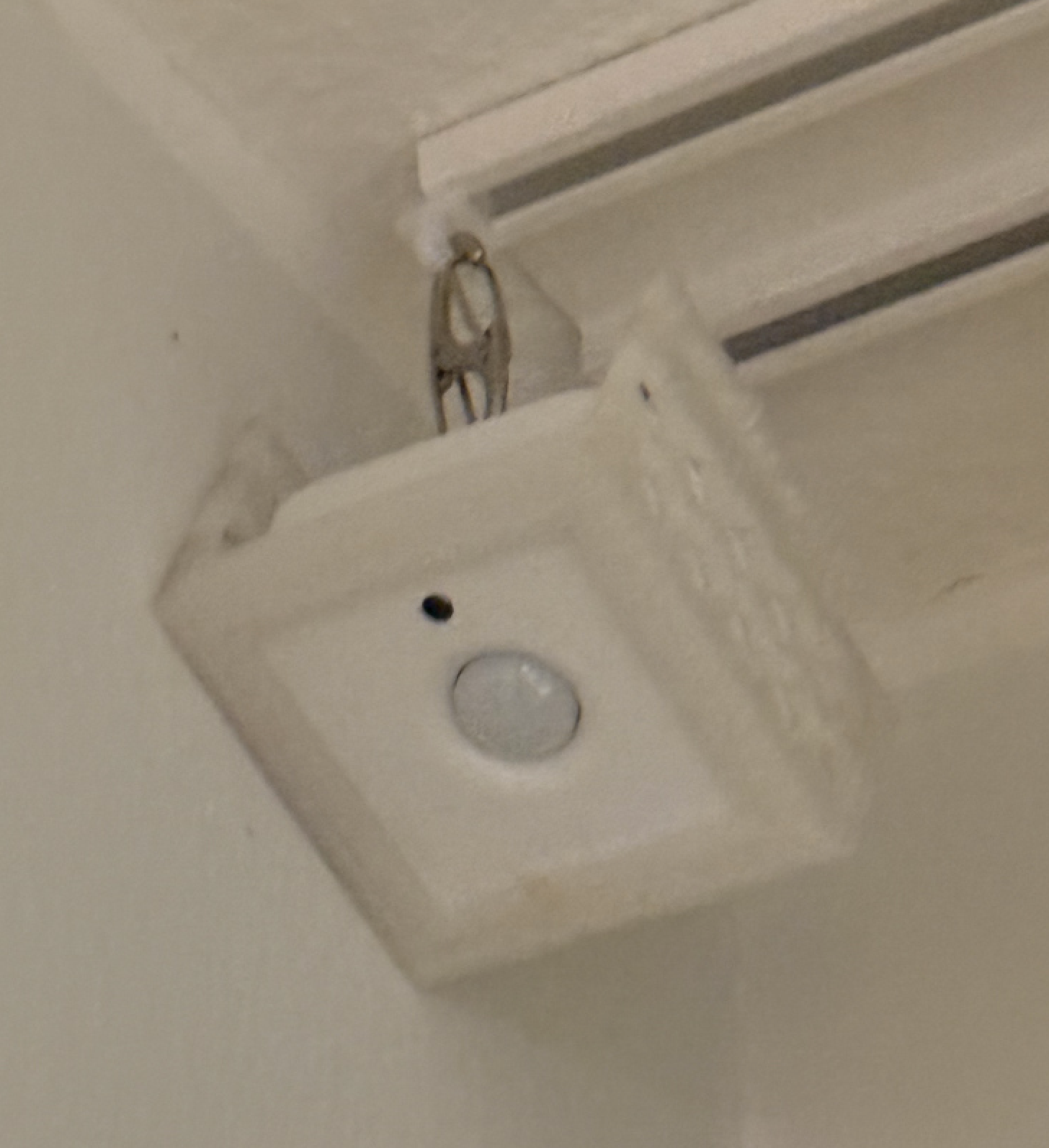

9 print attempts, 4 of them completed (two of them final design). I’m happy with the outcome, as now I do not have the motion sensors around desks anymore but instead they hang from the curtain rail like this:

Here’s the public page of it in case you want to print it yourself: Philips Hue Motion sensor cage by damezumari